How is Sheathing Application Made? Illustrated Lecture, How is Thermal Insulation Made?

As sheathing companies , 3 different sheathing techniques are applied asinterior cladding, exterior sheathing and sandwich wall. The best program that can be done to prevent the formation of thermal bridges and to ensure the continuity of the insulation is the application of exterior cladding , that is, thermal insulation. When the exterior cladding is made in the buildings , the energy savings that will ariseand the contribution of the thermal insulation to the family and country economy has become an important issue today. Both the decrease in natural energy resources and the high energy costs are the most important early stages of this situation.

Sheathing applications that are planned to be made in buildings contribute to the protection of nature and energy resources and come to the fore as one of the best measures to prevent damage to the environment . The heat insulation application, which contributes to the country and family economy, goes through a certain sequence of operations and stages. The order of the sheathing process and the application stages are an issue that should be given importance for a healthy insulation application .

The sequence of operations during the jacketing application is as follows;

The 1st Stage is the Preparation Stage before the Sheathing Application .

- How to make the best jacketing? If we ask, the first thing we need to know is; Sheathing should be done between +5°C and +30°C .

- Before starting the sheathing application , glass, wood, etc. on the facade of the building. Building elements must be protectedagainst contamination and damage.

- The general exterior of the building where the application will be made and the surface on which the " heat insulation " will be applied should not be damp, the floor screeds, interior and exterior wall plasters should be dry.

- The surfaces on which sheathing will be applied , should not contain residues that may reduce the adhesion quality of the sheathing materials , should be free from oil and dust-free.

- On the surface where sheathing will be applied, there should be no moisture that develops upwards from the soil, and the waterproofing application ( drainage ) must be completed so that it reaches at least 30 cm above the soil.

- Existing coatings (primers, paint and old plasters) on the facade of the building should be checked in terms of durability, if it is considered that they are not strong and durable, they should be removed. However, if any, cracked or swollen surfaces should be repaired, a solid and clean floor that will not spill should be obtained for the sheathing application .

- If there are curvatures exceeding 2 cm on the surface to which the heat insulation plates will adhere, they should be smoothed with rough plaster before the sheathing applicationConsidering the climatic conditions, the facade is protected from sun, rain, snow and wind, etc. After protection, jacketing application should be started.

- Exterior rain gutters, cables, etc. It should be placed on the thermal insulation system and placed at a distance of at least 6 - 7 cm. If desired , it can be hidden by means of U jamb profiles . Concealing the gutter and the rained down pipes both ensures its durability for many years and adds visuality to the building as a design. At this point, you can benefit from u jamb coatings .

How Should a Good Sheathing Be?

In exterior sheathing applications, thermal insulation system materialsshould be stored in a dry and cool environment so that they will not be deformedin order to ensure working safetyExterior cladding materials should be kept in good conditions and should not be stored in environments with humidity, mold and excessive heat.

The 2nd Stage is the " Water Basin Profile " Installation While Exterior Heat Insulation is being made.

During the Metpor Jamb & Sheathing application , the installation of the sub-basement profile ensures that the thermal insulation assembly is balanced and smooth . In order to correct possible curvatures on the surface, the gaps, recesses and protrusions between the wall and the sub- basement profile are corrected with wedges of different thicknesses, the surface is squared and mounted with dowels (Picture 1 and Picture 2).

A gap of 2-3 mm should be left between the end-to-end profiles. Corner connections are formed by cutting and joining the sub- basement profiles at a reasonable angle to the corner. The size of the sub-basement profile should be chosen considering the thickness of the thermal insulation board to be used. ( Picture.3 ).

The 3rd Step is the " Adhesive Mortar " Preparation and Application Stage.

In METPOR Jamb and Sheathing applications , the adhesive mortar should be prepared in accordance with the instructions written on the package. The rate of water to be used at this point, etc. Factors such as sheathing will directly affect the adhesion of the sheathing adhesive. Depending on the curvature or smoothness of the surface to be sheathed, the application method of the insulation adhesive mortar changes.

If the surface is smooth, the " Whole Surface Adhesion Method " is applied and the bonding mortar is applied to the entire exterior cladding plate with a trowel or a similar notched trowel (Picture 1).

If there are differences in level or curvatures on the surface, the " strip and point application method " is applied, and the adhesive mortar is applied to the back of the heat insulation board as a strip uninterruptedly along all the edges, and to the middle parts with a trowel ( Picture 2 ). In this method, 40% of the thermal insulation board surface should be covered with adhesive material .

When applying adhesive mortar to the back of the exterior sheathing and thermal insulation board, care should be taken that it does not overflow from the edges (Picture 3).

The 4th Step is Briefly Installation and Placement of Thermal Insulation Boards in Sheathing Application.

During the application of Metpor Sheathing & Jamb , the thermal insulation board , on the back of whichadhesive mortar is applied, should be placed on the sub-basement profile without any gaps ( Picture 1 ). While the sheathing application is being made, the sheathing boards are adhered to the wall by sliding slightly, paying attention to full contact with the wall. Plate levels should be controlled with a gauge or spirit level ( Picture.2 ).

The heat insulation boards are laid continuously and staggered upwards, starting from the lower part of the wall . In the corners, sheathing plates should be placed in a staggered manner ( Picture.3 ).

Care should be taken to lay the heat insulation boards properly and not to damage the edges . Damaged insulation boards should not be used, and sheathing boards with worn edges should be filed before application. No gaps should be left between the boards during placement , and thin gaps should be filled using insulation tape orfoam.

Step 5 Sheathing Anchor is the Doweling of Thermal Insulation Boards.

During the exterior sheathing application , a mechanical connection with the dowel is provided to prevent damage from the effects of the wind suction power, at least 24 hours after the thermal insulation boards are bonded, and to ensure the continuity and performance of the layout

The most appropriate number of anchors to be used is determined by the height of the building and the environmental conditions of the building. At least 6 dowels per square meter are applied to the building surface, 4 to the junction points of the plates, especially horizontally and vertically, and 2 to the square .

The number of dowels to be used in the plates made on the corners of the building is increased due to the wind power. 6 dowels should be used up to 8 meters high, 8 anchors between 8 and 20 meters, and 10 anchors at 20 meters and above .

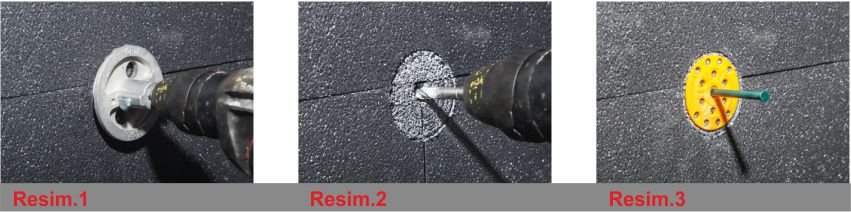

Sheathing anchor application should be applied at least 10 cm from the inside in addition to the plate thickness at the corner points of the buildings. The sheathing anchor to be used should be chosen according to the wall characteristics. In order for the head of the sheathing dowel to be fully inserted and not to form a thickness, acountersunk head must be opened using the apparatus (Picture 1).

In sheathing, the point where the dowel will be mounted is drilled with a drill . The hole length should be 1 cm larger than the dowel length ( Picture.2 ).

Dowel nails are completely nailed by placing dowels into the drilled dowel hole ( Picture.3 ).

After the dowels are placed in the countersunk cavity, the remaining gaps around the dowel are filled with the same plaster before the first layer of plastering .

In order to obtain a smooth exterior surface , the dowel heads must be mounted in the same area as the insulation board surface .

Step 6 : Meshed PVC Corner Profile , Angle Profile Application.

Step 6 : Meshed PVC Corner Profile , Angle Profile Application.

While " sheathing systems " are applied in buildings, building edges and corners ( Picture.1 ), windows ( Picture.2 ) and door edges ( Picture.3 ) are the areas where the risk of cracking is high and mechanical stresses are highest. Meshed pvc corner profile is used in Metpor Jamb & Sheathing Application to obtain smooth corners that can withstand impacts .

The corner profile is placed in the first layer of plaster mortar by applying a thin layer of plaster and reinforcement mesh is applied on it. Using mesh corner profiles saves both labor cost and time. It also minimizes the danger of incorrect application that may occur during the assembly of the meshed corner profile .

The 7th Step is Formation of Plaster Mortar Layers and Application of Reinforcement Mesh .

The 7th Step is Formation of Plaster Mortar Layers and Application of Reinforcement Mesh .

As Metpor Jamb & Sheathing , how can we make the best jacketing? If you ask, the first layer surface plaster program is made after the bonding and doweling of the thermal insulation boards . In the prepared jamb coating application , the plaster mortar is applied homogeneously to the surface by means of a steel trowel (Picture 1). The program thickness of the surface plaster should be maximum 2 mm in each layer.

The reinforcement mesh should be placed on the first layer surface plaster that has not yet dried, by pressing it from top to bottom and stretching it well, without being folded and at an equal distance from the insulation board to the entire surface. Reinforcement mesh should always be applied by overlapping 10 cm at the junction areas ( Picture.2 ).

Before the first layer of plaster dries, at least 3-4 hours later, depending on the air temperature, the second layer of plaster is applied. During the application, in order to prevent the thermal insulation reinforcement mesh from slipping out of place or embedding in the first layer of plaster mortar, depending on the weather conditions, the second layer plaster mortar program is completed by waiting for the first layer plaster mortar to release its water slightly ( Picture.3 ). Thus, the surface becomes suitable for the exterior cladding.

Step 8 is Decorative Plaster Coating and Top Coat Coating Application.

- After the 7-day drying period of the applied sheathing plaster mortar, the decorative final layer coating stage is started.

- In Metpor Jamb & Sheathing application, mineral textured decorative plaster is applied to the surface with a trowel (Picture 1).

- Before it dries, it is passed over with a plastic trowel to form texture on the surface (Picture 2).

- Finally, the exterior primer and paint program is made (Picture 3).

Preferences such as decorative biscuit brick, glass, mosaic (BTB) facade cladding can cause problems. "The general technical specification of thermal insulation", the top coat coatings to be used on thermal insulation systems are clearly explained. As Metpor , we do not recommend applying a second top coat on sheathing .

How to Make the Best Sheathing?

If the adhesive mortar to be used in the exterior sheathing program contains cement, +5 to +30 degrees is ideal as possible. Before the application , drain pipes, dish antenna etc. in the building. must be dismantled. Cracks, old plaster and dismantled areas should be repaired. Moisture on the facade should be removed before application. It is recommended to protect the scaffolding established during the application of insulation in rainy weather , by covering it with a protective net and nylon. We do not recommend applying sheathing in cold weather conditions such as frost.

Accordingly, acrylic or silicone-based decorative ready-made plasters with line or grain textures, and facade coatings with grainy texture will be the most ideal choice for system programs . With these recommended options, possible plastering problems on the façade will be eliminated and an exterior claddingnot visually disturb the completion of the work will emerge. How is Thermal Insulation Made? How to make the best jacketing with the illustrated explanation with the above itemsWe have answered the question. You can also benefit from our Insulation , exterior cladding models , exterior cladding panels article.

You can achieve 50 - 60% energy efficiency, as well as heat savings, through thermal insulation materials applied on the exterior . Because in a detached house with no insulation, the level of heat escaping to the outside is extremely high. Building exterior cladding materials are generally selected and applied ideally to the design and aesthetic appearance of the building.

In Turkey , mostly wood, precast, american siding, siding coatings , sheathing panels , composite (alucobont), granite, aluminum, natural stone and glass facade coatings are used. There are certain stages for applying sheathing. What is sheathing for buildings ? How is it done? After answering the question, the next steps should be taken.

If one of the most important stages is the building where the application will be made, the jacketing decision must be taken . The next important step is the selection of the exterior coating company , which offers the most affordable price among the sheathing companies and has the potential to handle the job . How to choose an exterior sheathing company? Our article is a resource that can guide you in choosing a company.

While choosing an exterior sheathing company, another subject should be researching the types of sheathing materials to be used. The heat insulation material to be selected should be covering materials at a level that will meet the needs of the building. You can reach detailed data by clicking on the link for thermal insulation material recommendation . One of the neglected issues while applying Thermal Insulation is the issue of occupational safety. The safety of the scaffold and the occupational safety of the working personnel should be taken and the risk of possible work accidents should be prevented.

Metpor

info@metpordekor.com

Okunma Sayısı : 158